Resilient, refined, and versatile.

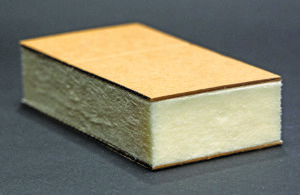

Low carbon cellulose wood foam is a natural alternative to fossil-based packaging foam.

Fibrease® Wood Foam Sustainable Packaging

The Next Generation of Packaging Foam offered exclusively in North America by Nature-Pack.

Engineering Solutions For A Circular Economy

Today we see a growing importance on using materials that are bio based, renewable, and can be recovered at end-of-life. Circularity must be incorporated into good design and Fibrease foam fits the bill. Starting with cellulose, nature’s most abundant polymer, a new type of wood foam has been engineered. This remarkable and innovative packaging foam utilizes a climate-friendly manufacturing process with reduced CO2 emissions versus traditional polymer foams. Fibrease foam has uniquely soft, flexible and lightweight (1.9 lbs/cu.ft.) attributes that mirror polyurethane (PUR) foam while delivering outstanding thermal performance (R-Value of R-4.1 /in) that exceeds expanded polystyrene (EPS) bead foam.

Features & Benefits

- Non-toxic, natural wood fiber, foam-in-place alternative with excellent cushioning and dampening properties.

- Superior, curb-side recyclable replacement for EPS foam in cold chain applications.

- Versatile fabrication methods, die-cutting, gluing, coating, laminating, skiving, and water jet cutting.

- Unique disposal profile allows primary & secondary packaging to be recovered and recycled with the paper stream.

- Optimal for reuse in closed loop systems.

Nature-Pack is proud to collaborate with Stora Enso to introduce Fibrease foam to the North American market.

We are now working with select clients who would like to incorporate a sustainable packaging foam alternative into their value chain.

Please contact a Nature-Pack specialist today and let’s get started!

The Perfect Balance: Fibrease natural wood fiber foam is renewable, recyclable and sustainable.